Введение

Для изготовления алюминиевых резервуаров для хранения нефтехимических продуктов, криогенных жидкостей или пищевых продуктов требуются присадочные металлы, которые придают исключительную прочность соединениям и стойкость к коррозионному растрескиванию под напряжением в целях эксплуатации. Наша проволока серии 5XXX разработана с учетом механических свойств обычных материалов, из изготавливаемых пластин резервуара (например, 5083), что обеспечивает высокую эффективность сварки и структурную безопасность. Консистенция провода приводит к минимуму дефектов, что имеет решающее значение для испытания неразрушающего контроля (НК) и поддержания номинального давления.

Спецификация

| Классификация (AWS) | ЭР5183/ЭР5356 |

| Ключевое свойство | Высокая прочность при низких (криогенных) температурах |

| Совместимость основных металлов | 5083, 5456 и другие пластинчатые сплавы с минимальным содержанием магния. |

| Ударная вязкость (типичная) | Поддерживается при температуре -196°С (криогенное применение) |

| Гарантия качества | Соответствует строгим требованиям неразрушающего контроля |

Приложения

-

Строительство крупных резервуаров для хранения нефти и газа.

-

Изготовление криогенных резервуаров для работы со СПГ и жидким кислородом.

-

Сварка производственных трубопроводов и силосов.

-

Производство сосудов под давлением, соответствующих требованиям норм ASME/API.

Оплата и доставка

-

Выполнение оптового заказа: Способен создавать большие объемы проволоки, необходимые для добычи крупной нефтебазы.

-

Поддержка проекта: Специализированные продажи и техническая поддержка для международных графиков поставок материалов в соответствии со сроками строительства.

-

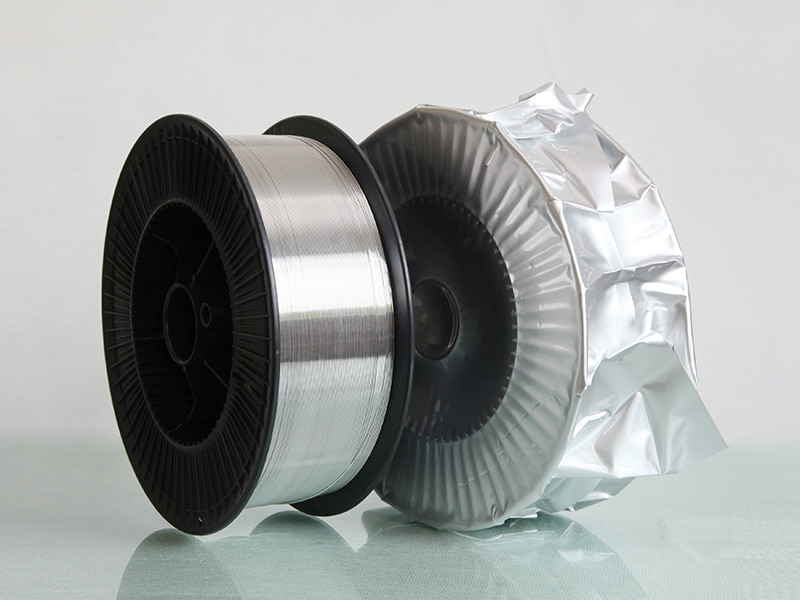

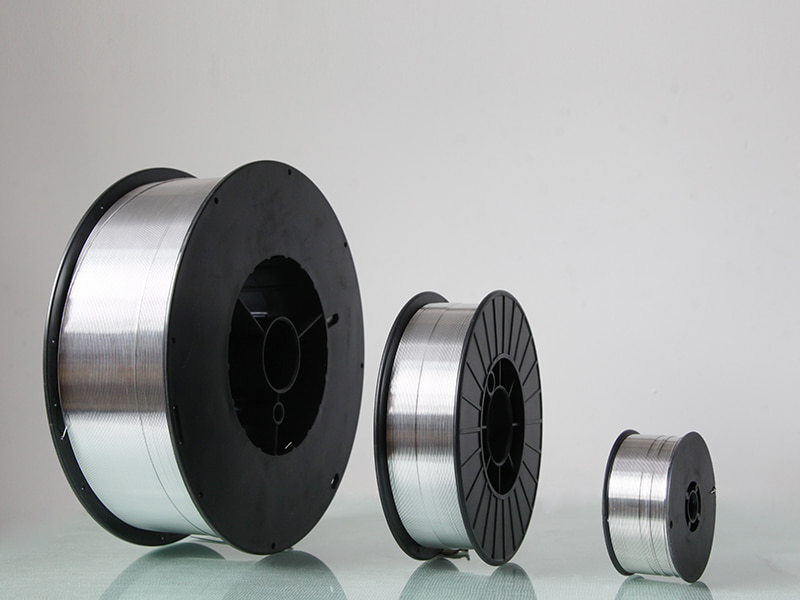

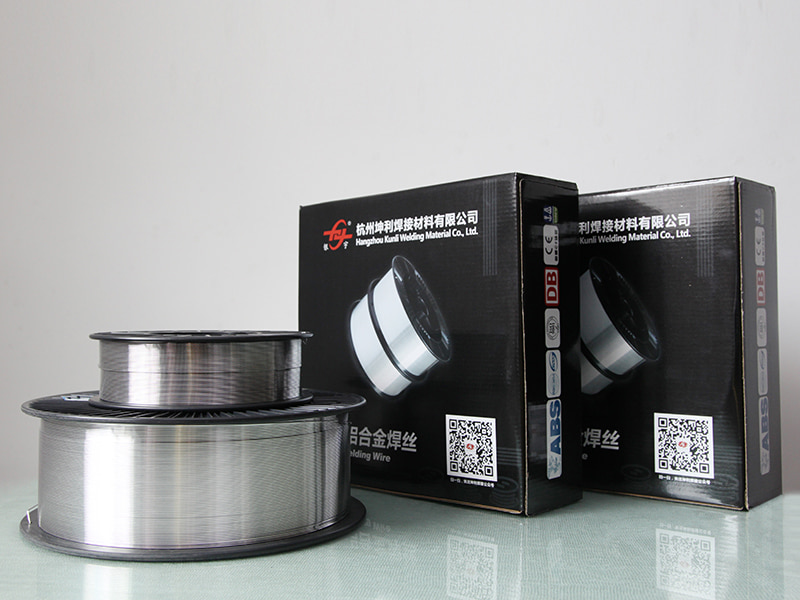

Упаковка: В барабанах предусмотрена большая емкость (если это возможно) для максимального увеличения времени горения дуги при сварке в полевых условиях.