Введение

Переход к уменьшению веса в автомобиле требует высоконадежных и эффективных материалов для сварки. Наши провода предназначены для рабочих линий и обеспечивают стабильные характеристики дуг при высоких скоростях движения, что важно для максимизации производительности и минимизации объемов работ. Мы уделяем особое внимание составу (4XXX и 5XXX), который обеспечивает прочные, пластиковые сварные швы, способные выдерживать ударную нагрузку и способствовать структурной общей безопасности, безопасности крышек и компонентов автомобиля.

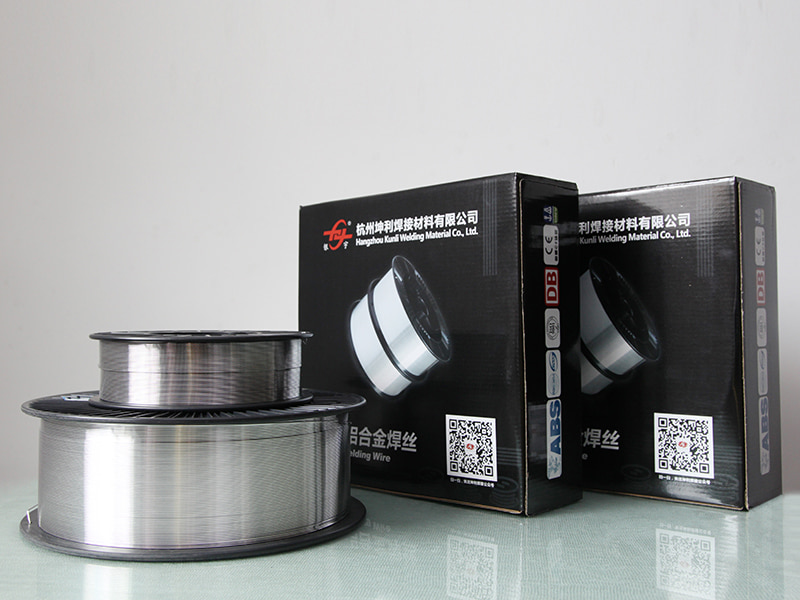

Спецификация

| Классификация (AWS) | ЭР4043/ЭР5356/ЭР5183 |

| Ключевое свойство | Пластичность и устойчивость к нагрузке |

| Совместимость основных металлов | Листовые и экструзионные сплавы серий 6061, 6063, 5000 |

| Отделка поверхности проволоки | Чрезвычайно незабываемо и чисто (подача с низким коэффициентом трения) |

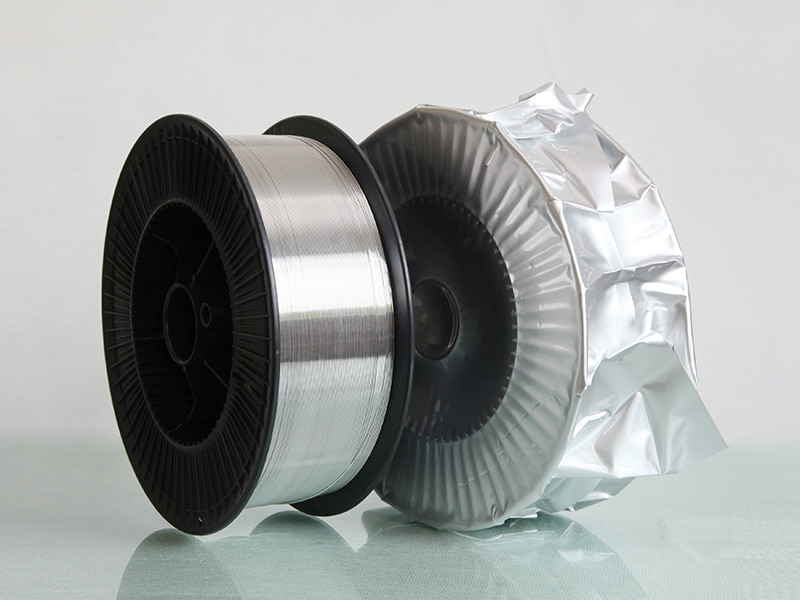

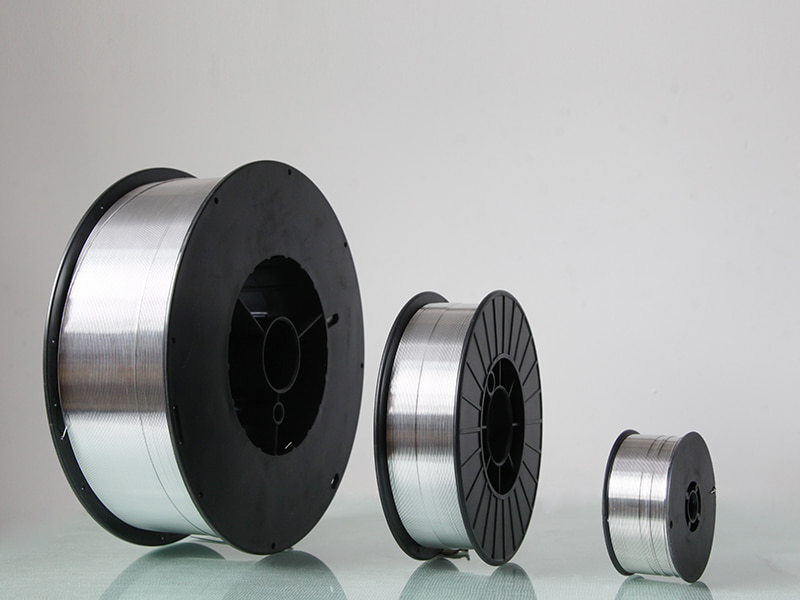

| Упаковка | Большие барабаны (около 200 кг) для непрерывной роботизированной подачи |

Приложения

-

Кузов в белом (BIW) сборка и соединение алюминиевых рамных шасси.

-

Сварка опор, элементов подвески и энергопоглощающих конструкций.

-

Изготовление алюминиевых дисков, бамперов и теплообменников.

-

Роботизированная сварка MIG и лазерно-гибридные процессы на предприятиях уровня 1 и OEM.

Оплата и доставка

-

Логистика: Специализированная логистическая поддержка крупных объемов запланированных поставок непосредственно на заводы по сборке автомобилей.

-

Условия оплаты: Договорные условия кредита на основе заключенных долгосрочных договоров поставки.

-

Контроль качества: Данные SPC (процессы статистического контроля) доступны по запросу для обеспечения стабильности составляющих.