Введение

Для изготовления современных железнодорожных вагонов требуются присадочные металлы, которые сочетают в себе высокую прочность на разрыв, усталостную прочность и эстетику гладкого сварного шва. Наши специальные составы проволоки, включая специальные сплавы с высоким содержанием магния, разработаны с учетом строгих стандартов безопасности и долговечности железнодорожной отрасли. Эти проволоки обеспечивают стабильные механические свойства сложных, длинных сварных швов, типичных для сборки вагонов поездов, что способствует снижению веса и повышению энергоэффективности транспортных систем.

Спецификация

| Классификация (AWS) | ЭР5087/ЭР5356 |

| Стандарт CRRC | Статус квалифицированного поставщика |

| Совместимость основных металлов | Алюминиевые сплавы серий 6000 и 7000 (термообрабатываемые) |

| Прочность на сдвиг (типичная) | 180 МПа - 210 МПа |

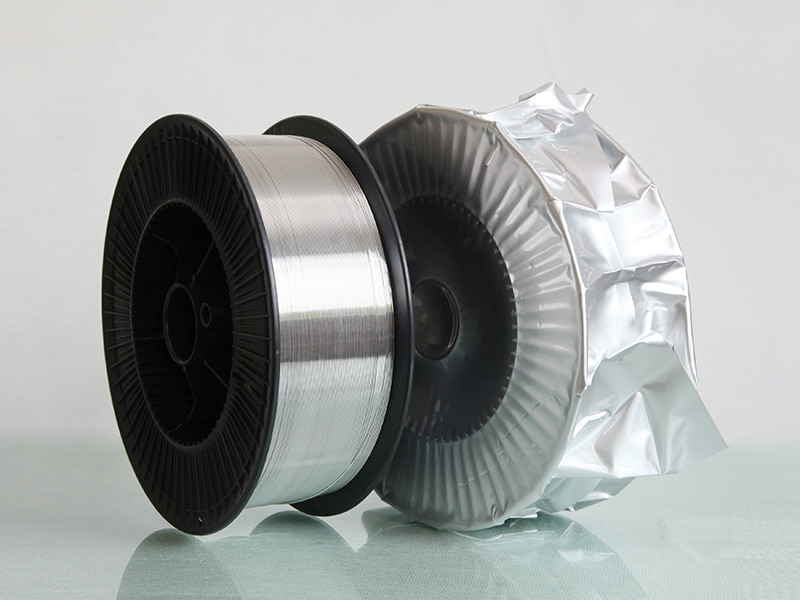

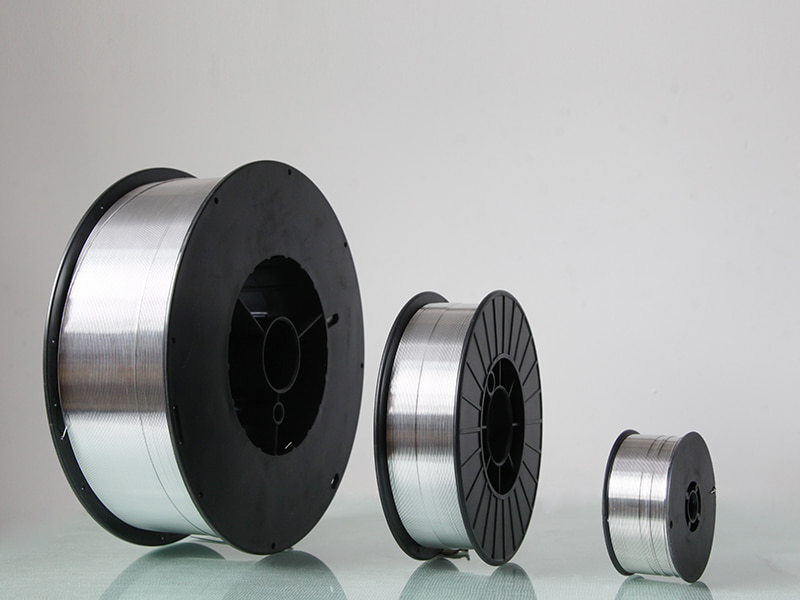

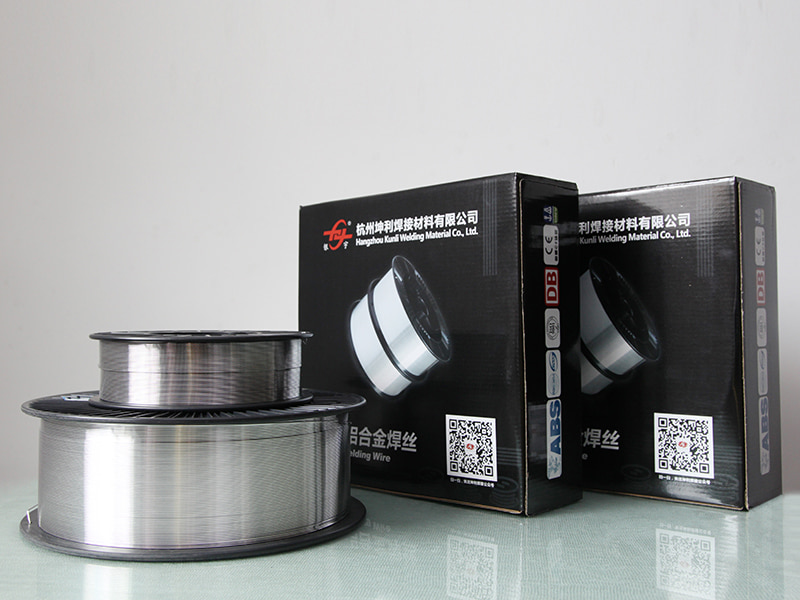

| Форма поставки | Катушки послойной намотки для роботизированной и автоматизированной сварки |

Приложения

-

Сборка алюминиевых кузовов и конструктивных элементов высокоскоростных поездов (например, проекты CRRC).

-

Изготовление салонов пассажирских поездов и багажных полок.

-

Сварка грузовых железнодорожных вагонов и контейнеров для перевозки сыпучих грузов.

-

Ремонт и обслуживание железнодорожной инфраструктуры и узлов.

Оплата и доставка

-

Управление запасами: Возможность держать буферный запас для крупных повторяющихся заказов, чтобы обеспечить доставку JIT (точно в срок) на производственные линии.

-

Изготовленная на заказ упаковка: Опция для больших барабанов или специализированных катушек для непосредственной интеграции с крупносерийными роботизированными сварочными системами.

-

Документация: Полная отслеживаемость материалов и сертификаты заводских испытаний (MTC) предоставляются с каждой поставкой.